Winters expose every weakness in a rooftop solar system — moisture, fog, temperature swings, metal

Read MoreFor most Indian businesses, electricity is no longer a predictable monthly expense. It has become a variable cost that directly hits margins, disrupts production planning, and affects long-term competitiveness.

Grid tariffs keep changing, making annual energy budgeting guesswork rather than planning. When power costs swing unpredictably, profitability does too and finance teams have very little control over it.

Backup systems don’t solve the problem either. Diesel generators are expensive to run, painful to maintain, and unreliable during long outages. Even with improvements in grid infrastructure, businesses still face power cuts, voltage fluctuations, and unplanned downtime.

Factories slow down, warehouses lose efficiency, and timelines slip losses that rarely show up clearly in financial reports but hurt operations every day.

That’s why B2B decision-makers are now seriously evaluating Hybrid Solar System for Businesses in India. Not for sustainability branding, but for control. Hybrid systems cut dependence on the grid, keep operations running during outages, and reduce exposure to peak-hour tariffs.

For businesses that care about scalability, predictable costs, and operational risk, hybrid solar is no longer a “nice-to-have.” It’s being assessed as core infrastructure just like machinery or logistics because the cost of unreliable power is now higher than the cost of fixing it.

A hybrid solar system integrates solar panels, grid electricity, and battery storage into a single power architecture. The system prioritizes solar generation, stores surplus energy in batteries, and draws power from the grid only when required.

This allows businesses to consistently use the lowest-cost power source without manual switching or operational intervention.

Unlike conventional grid-tied solar systems, hybrid systems continue supplying power during grid outages. Unlike diesel generators, they do not depend on fuel logistics, frequent servicing, or variable operating costs. Power availability remains stable and predictable, supporting uninterrupted operations.

For commercial and industrial users, this results in lower energy costs, reduced exposure to peak-demand charges, and reliable backup power. Hybrid systems are particularly relevant for factories, warehouses, cold storage, and logistics facilities where power interruptions or quality issues directly affect operational continuity and revenue.

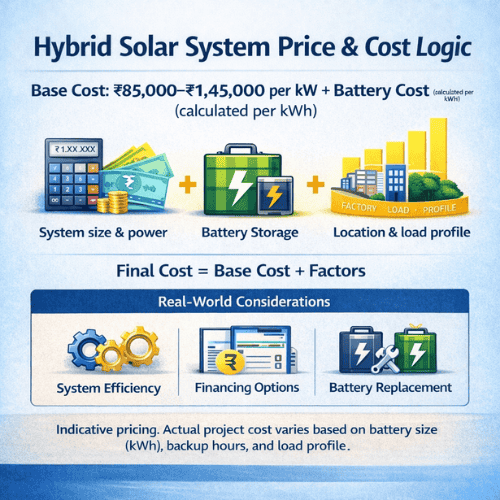

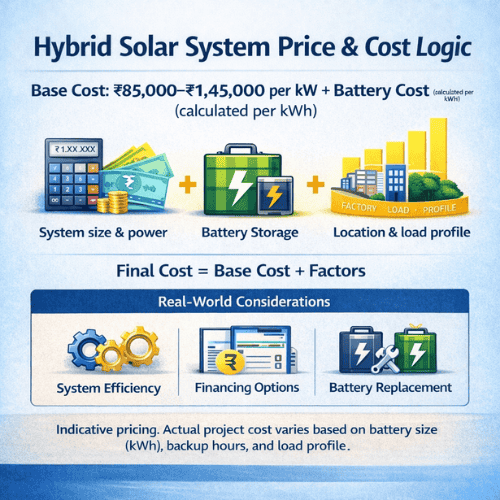

The cost of a hybrid solar system for businesses in India depends on three variables: system capacity (kW/MW), battery storage size (kWh), and the facility’s day versus night power consumption profile. Evaluating any one of these in isolation leads to incomplete and often misleading pricing.

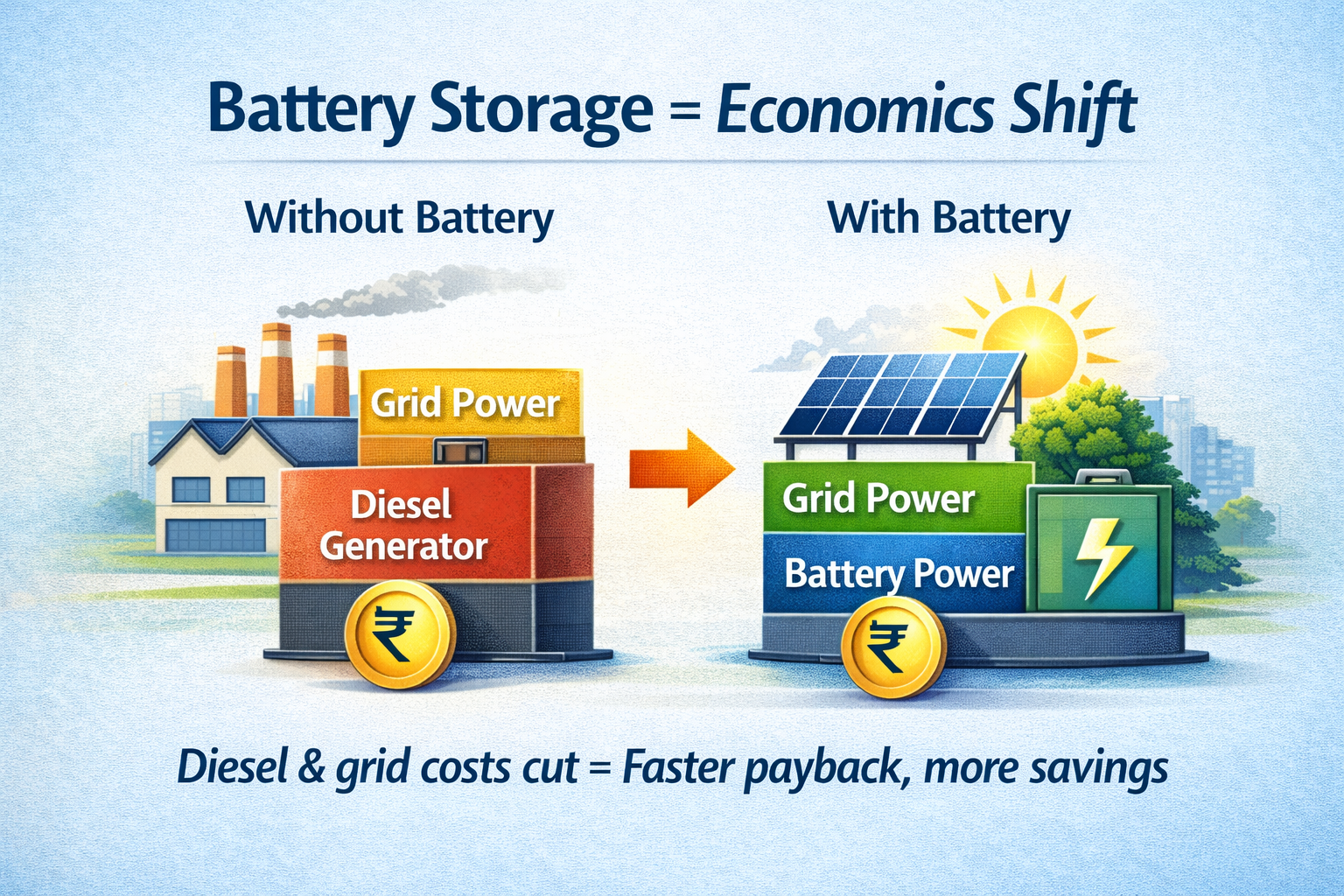

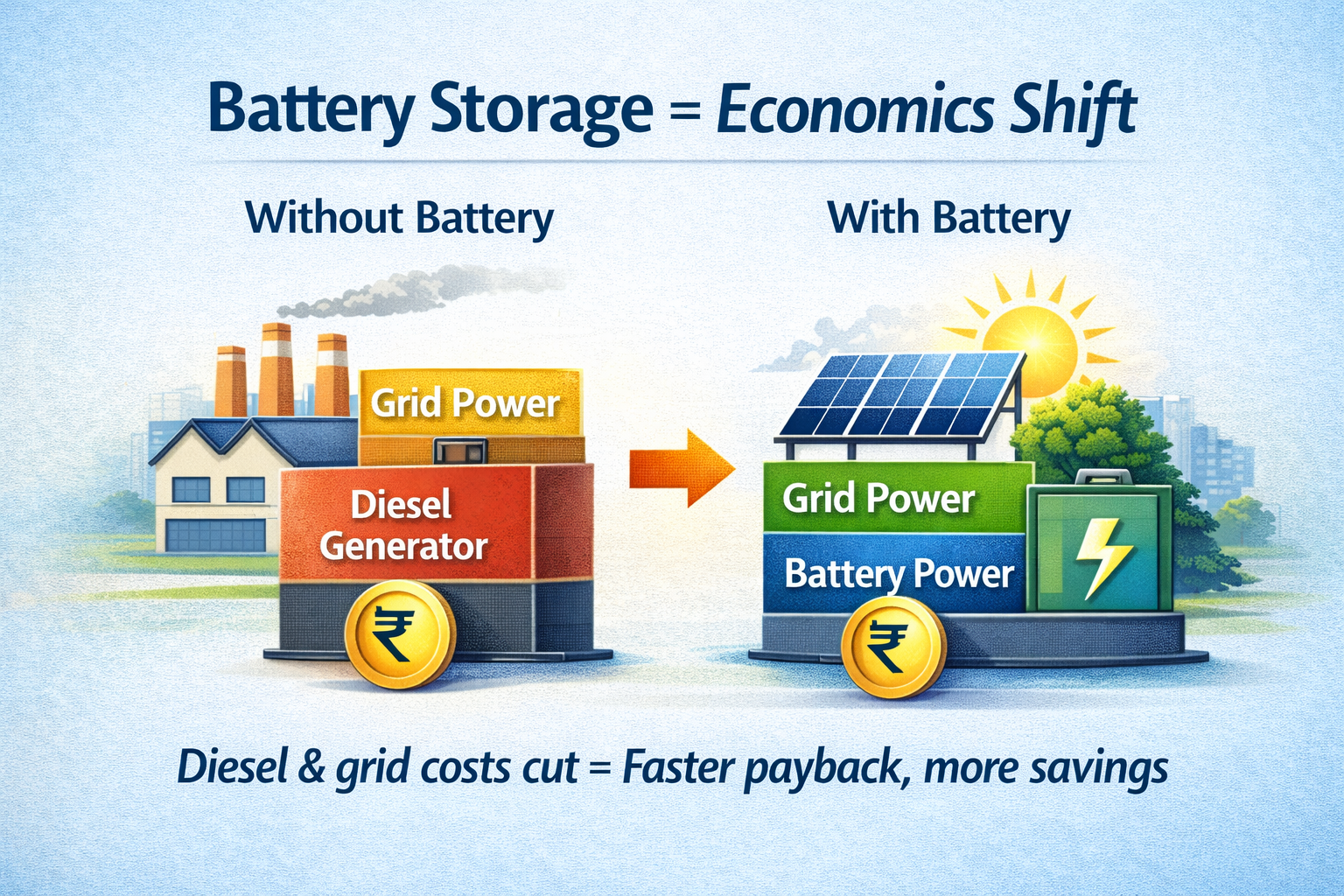

At the commercial scale, solar systems without battery storage involve lower upfront costs but provide limited backup and no insulation from grid outages or peak-hour tariffs. Systems with lithium battery storage require higher initial investment, but they offer greater control over energy costs, ensure power continuity, and enable tariff optimization.

For factories and warehouses, batteries typically represent 30–45% of total system cost. This is also where most of the value is generated. Battery energy storage system reduces diesel dependence, avoids peak-demand penalties, and mitigates losses caused by downtime.

As a result, informed businesses assess hybrid solar systems based on lifetime energy cost rather than installation price alone. Hybrid systems are most effective in facilities where downtime, diesel usage, and tariff exposure directly affect operating margins.

Direct subsidies for commercial and industrial hybrid solar systems in India are very limited. Factories, warehouses, and large commercial facilities should not expect meaningful upfront government support for project costs. Most subsidy programs simply do not apply to C&I solar installations.

Government incentives are largely directed toward residential rooftops, agriculture schemes, and manufacturing-linked programs such as PLI for equipment producers. These policies are meant to encourage adoption and manufacturing, not to subsidize electricity costs for high-consumption businesses.

Businesses benefit indirectly, not through cash subsidies. Mechanisms such as accelerated depreciation, state-level electricity duty reductions, and open-access or captive consumption models help lower the effective cost of solar power over time. These advantages improve cash flow and long-term energy economics.

If a hybrid solar power projects is being sold mainly on “subsidy savings,” that is a warning sign. The real value of hybrid solar lies in operational savings—reduced grid dependence, lower diesel usage, avoided peak-demand charges, and protection from downtime. For serious businesses, hybrid solar is about control and predictability, not subsidies.

Solar power without battery storage system for factories reduces electricity costs only during daylight hours. It does not address peak-hour tariffs, grid outages, or power requirements during evening and night-time operations.

For facilities operating multiple shifts or running sensitive equipment, this results in continued reliance on high-cost grid power and diesel generators.

Battery energy storage changes how solar power is economically used. Excess solar energy generated during the day is stored and discharged during peak tariff periods or grid failures. This reduces exposure to the most expensive electricity units, maintains operational continuity, and lowers diesel consumption across the facility.

For commercial and industrial users, storage is not primarily a backup feature. It enables tariff optimization, stabilizes long-term energy costs, and reduces operational risk from outages and price volatility. When evaluated over the system’s lifecycle, battery storage materially improves the financial performance of solar power for businesses.

Factories run on heavy power loads. Machines don’t like interruptions. They don’t like voltage ups and downs either. Even a short power cut can mess up a batch, slow a line, or force a restart. Sometimes you see the loss immediately.

Sometimes it shows up later as quality issues or higher maintenance. That’s why power reliability isn’t optional in factories. It’s basic operations.

In a factory, solar with storage is usually set up as a hybrid system. Solar power is used directly when the plant is running. If there’s extra power, it goes into the battery. When the grid goes down or power becomes expensive, the battery takes over.

This way the factory depends less on the grid during peak hours and doesn’t have to rely on diesel every time there’s an issue.

Battery size is not decided to run the factory fully off-grid. That’s rarely the goal. It’s decided based on what cannot stop, how long backup is needed, and how many shifts the plant runs. The aim is simple. Avoid production loss. Reduce diesel usage. Keep costs predictable. Keep the plant running.

Warehouses have a distinct energy profile compared to manufacturing facilities. Equipment loads are relatively lower, while dependence on lighting, HVAC systems, and material-handling operations is high, particularly during evening and night-time hours.

In this environment, power reliability is essential for operational continuity, worker safety, and inventory protection. Battery energy storage in warehouse applications is primarily used for cost optimization and power stability rather than heavy-load backup. Solar energy generated during the day is stored and discharged during peak tariff periods to reduce exposure to high-cost grid power.

During outages, battery systems maintain essential operations without relying on diesel generators, which involve higher operating costs and maintenance requirements.

Hybrid solar systems for warehouses are generally smaller in capacity but deliver high savings efficiency per unit of energy. Predictable load patterns and defined peak usage allow storage systems to be accurately sized, resulting in consistent cost savings, stable operations, and improved energy cost control over time.

In 2026 most commercial and industrial users, a hybrid solar system is worth evaluating if power reliability, cost predictability, and operational continuity are priorities. These systems address multiple energy risks that cannot be managed through grid power, diesel backup, or solar-only installations in isolation.

Grid-only power offers limited control over tariffs, outages, and supply quality. Diesel generators provide backup but involve high and volatile operating costs. Solar-only systems reduce daytime electricity expenses but do not ensure reliability during outages or peak demand periods. A hybrid solar system integrates these sources in a controlled manner, balancing cost efficiency with reliability and scalability.

As a result, senior business leaders are increasingly assessing hybrid solar systems as long-term infrastructure assets rather than experimental projects. The value is reflected in more predictable energy costs, reduced exposure to operational disruptions, and improved long-term competitiveness.

Don’t ask, “What is the cheapest hybrid solar system price in India?” That question leads to short-term decisions and long-term regret. Cheapest systems cut corners on storage, design, and reliability, exactly the things that matter once the system is live.

Ask instead, “How much control do I gain over my energy costs in the next 10–15 years?” Control over tariffs, outages, diesel dependency, and peak charges is where the real value sits. That’s what protects margins when power prices rise and operations scale.

This mindset shift is the real difference. Some businesses keep reacting to power problems every year. Others design them out once and move on to growth.

If you’re evaluating hybrid solar for a factory or warehouse and want to understand whether battery storage makes financial sense for your operations, the next step is to find Sun Photonics, we help business like you in the matter of solar power installation for your business, to solar advisory for industrial facilities.

Jatin Singh is a content developer at Sun Photonics Pvt. Ltd., specializing in creating impactful content for solar energy solutions. With a background in tech and health, he has previously worked in digital marketing and pharma. Passionate about sustainability, and currently exploring all things about solar!

Approval by an Expert:

“This content is reviewed and approved by Dr. Sujata Bhaker, who holds a Doctorate in Renewable Energy and brings over 10 years of industry expertise.”

Winters expose every weakness in a rooftop solar system — moisture, fog, temperature swings, metal

Read MoreAs India accelerates its path toward clean and sustainable green energy, the role of Solar

Read MoreIndia’s energy sector is transforming rapidly, and commercial rooftop solar has emerged as a core

Read MoreIntroduction: Why BIPV Is Gaining Traction in India (2026 Update)Cities are growing taller, streets are

Read MoreChoosing the Best Solar System for Industries is not just about going green — it’s

Read More