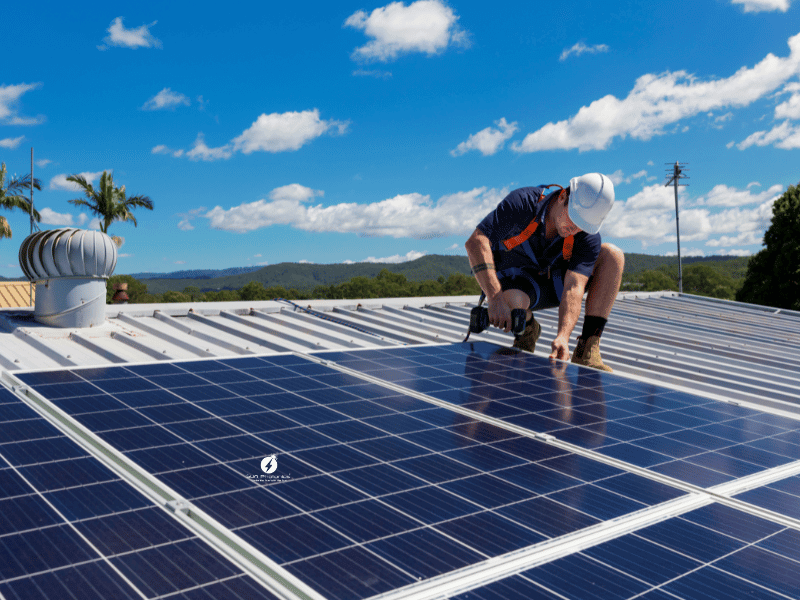

At Sun Photonics, we provide reliable and performance-focused solar operation and maintenance services for large-scale, commercial and industrial solar projects. Our experienced O&M team works with one clear goal — keeping your solar plant running efficiently and consistently over its full lifecycle.

We focus on preventive maintenance, real-time performance monitoring, and quick issue resolution to minimize downtime and protect long-term generation. For businesses looking for dependable Solar plant Maintenance Services in Gurugram, we offer structured maintenance plans, on-ground technical support, and transparent performance reporting.

With Sun Photonics, solar O&M means stable generation, controlled operating costs, and peace of mind that your asset is managed by professionals.

Regular, proactive maintenance is critical to maintaining consistent generation and preventing avoidable performance losses. Sun Photonics delivers a structured solar operation and maintenance services program focused on early fault detection, system reliability, and long-term asset protection, ensuring your solar plant operates at peak efficiency throughout its 25-year lifespan across commercial and utility-scale projects.

Dust, pollution, and everyday environmental buildup slowly cut into solar generation if modules aren’t cleaned at the right time. Our module cleaning schedules are planned around site conditions and seasonal dust levels, helping maintain consistent output without over-cleaning, an essential part of reliable solar module cleaning services.

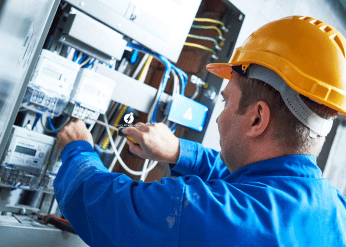

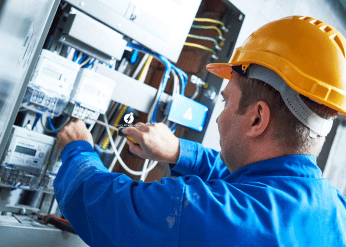

Loose connections and aging cables are easy to miss, but over time they quietly eat into your plant’s energy output. That’s why we regularly check every critical electrical connection, catching issues early before they turn into inverter problems or safety risks. This hands-on approach keeps your solar plant running smoothly through consistent solar electrical maintenance.

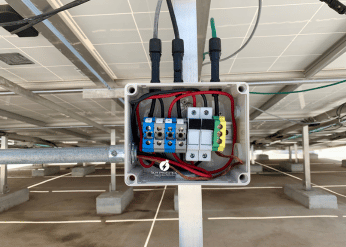

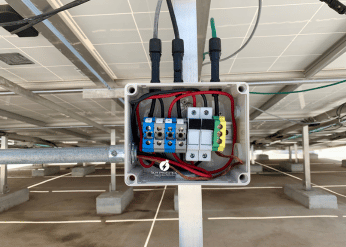

Junction boxes are exposed to heat, moisture, and dust, making routine inspection essential. Our checks focus on sealing, wiring health, and thermal stress to prevent short circuits and long-term system damage as part of our solar plant maintenance services in Gurugram.

Inverters are the heart of your solar plant, and even small issues here can lead to major generation losses. We carry out regular inverter servicing that includes visual checks, cooling system maintenance, and performance diagnostics. This helps catch problems early, avoid unexpected shutdowns, and keep power conversion running reliably day after day.

A solar plant is more than just panels and inverters. Monitoring systems, auxiliary power, security, and communication networks all need to work together. We regularly service balance of plant components to make sure data flows correctly, safety systems stay active, and the plant operates smoothly without interruptions.

Uncontrolled vegetation may look harmless, but it can cause shading, restrict access, and reduce overall generation. We manage on-site vegetation proactively to keep panels clear, maintain safe access routes, and ensure sunlight reaches the modules without obstruction throughout the year.

Unscheduled maintenance is critical when a solar power plant faces sudden issues like inverter trips, cable faults, or protection failures. These problems can stop generation instantly if not handled fast. With responsive unscheduled solar maintenance, faults are identified quickly and corrected to reduce downtime, protect equipment, and stabilize plant performance.

Typical solar O&M services during breakdowns include inverter troubleshooting, DC and AC fault rectification, SCADA alarm analysis, and hotspot correction. Since inverters directly impact generation, solar inverter maintenance is always prioritized. Fixing small issues early helps avoid major power losses and repeat shutdowns.

Civil maintenance supports long-term plant reliability by keeping site infrastructure in working condition. This includes maintaining control rooms, cable trenches, access roads, and drainage systems. Proper solar civil maintenance prevents water damage, safety risks, and recurring electrical faults that often arise from neglected site conditions.

Even when a plant generates power efficiently, faulty evacuation can cause revenue loss. Solar transmission line maintenance covers HT and LT line inspections, cable joint repairs, insulator checks, and pole maintenance. These activities ensure safe power evacuation, grid compliance, and uninterrupted energy delivery.

Continuous monitoring and tracking help keep a solar power plant under control, not guesswork. Through real-time performance data and SCADA systems, plant output, alarms, and deviations are tracked daily. This also ensures warranty obligations are monitored properly and supports insurance claims by providing clear fault history and coordination with external service providers. Strong solar monitoring and tracking is what turns data into timely action.

Delayed repairs often occur because the correct spare part isn’t available. Effective solar spares management ensures critical components like mounting structure parts, junction and combiner boxes, fuses, and DC–AC cabling are stocked and ready. This reduces plant downtime, avoids emergency procurement, and keeps maintenance costs predictable.

Catching fault in running a power plant is an important task when anything happens to a solar power plant, because when something is really faulty at that time, then guesswork won’t do anything at that time. Faster diagnosis means quicker recovery and fewer repeat problems.