Let’s face it — Haryana isn’t just a solar-friendly state. It’s one of the most profitable regions in India for commercial and industrial solar energy adoption. Businesses in Gurugram, Faridabad, Panipat, Hisar, Sonipat, Yamuna Nagar, Karnal, Ambala, Rewari and Rohtak face rising daytime tariffs, increasing fixed charges and heavy dependence on grid power.

Solar is the only long-term energy. A properly engineered solar plant cuts electricity costs from day one and locks your power price for the next 25+ years — with an average payback period of 4 to 5 years across most industrial zones in Haryana.

We deliver commercial and industrial rooftop, carport and ground-mounted solar EPC projects designed for Haryana’s load patterns, DISCOM procedures and climate conditions. We also execute government tenders, KUSUM projects and private PPA installations.

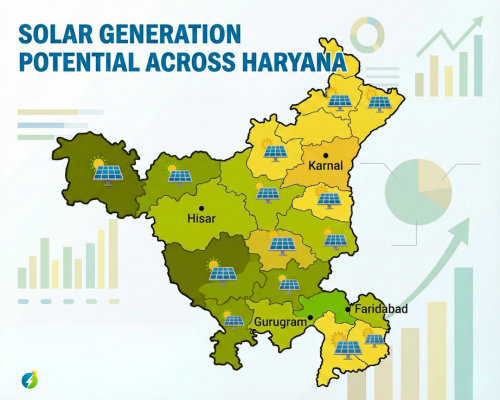

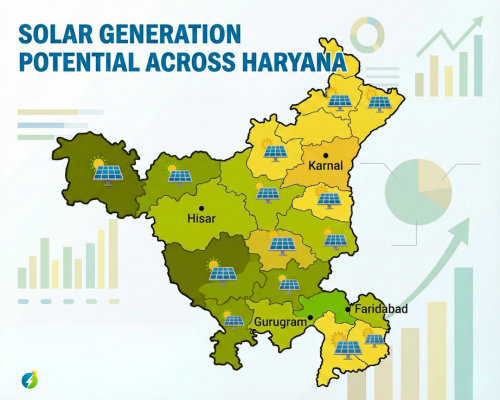

Haryana receives strong solar exposure, with average daily irradiation of about 5.0–5.5 kWh/m²/day, making it a high-potential state for solar generation.

Under normal operating conditions, a 1 kWp solar system typically produces 4–5 units per day. However, for accurate ROI planning and financial modelling, a conservative generation range of 4.0–4.5 kWh/kWp/day should be used.

Using a fixed assumption of 4.8 kWh/kWp/day across all districts is optimistic and can overstate output in areas affected by shading, dust load, or seasonal variation.

If you’re running a commercial or industrial unit in Haryana, you already know this — electricity isn’t cheap anymore.

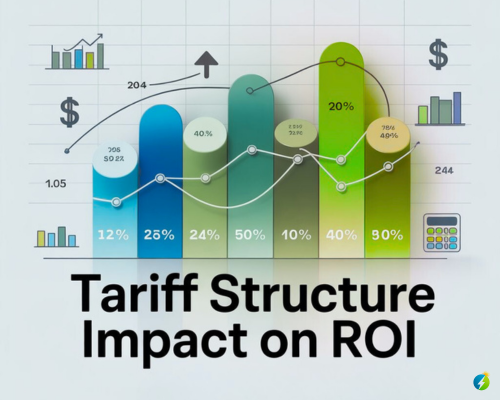

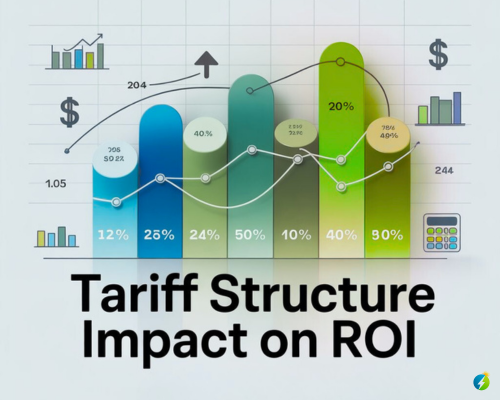

Across DHBVN, UHBVN, and HVPNL zones, power tariffs typically fall between ₹7.5 and ₹11 per unit, depending on your contract demand and consumer category. And while usage changes, fixed charges keep rising almost every year.

That’s exactly why solar shifts from being an option to a business decision.

A professionally designed solar plant helps you:

The result? Most projects recover their investment in 4–5 years across Haryana, and in some industrial belts, even faster — around 3.5 years.

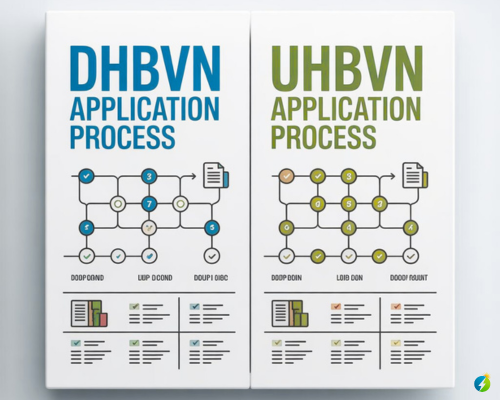

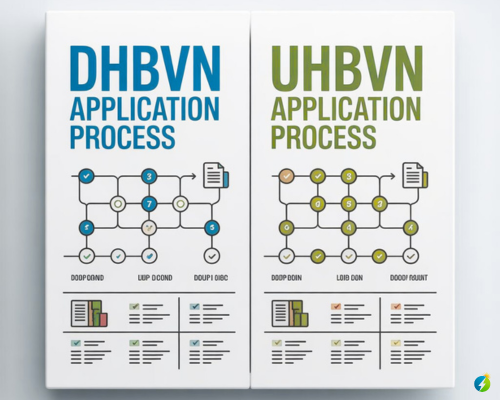

Haryana has one of the most regulated — yet clearly structured — solar approval systems in India. Depending on where your project is located, your application will fall under either DHBVN or UHBVN, and each follows its own processes and documentation rules.

That means approvals, timelines, and compliance requirements can vary by district — even within the same state.

All solar projects in Haryana operate under:

What this means for you:

Important:

Most policy information available online is outdated.

DISCOM circulars change frequently.

Always verify the latest rules before signing an EPC contract.

If your plant falls under DHBVN (Gurugram, Faridabad, Hisar, Rewari, Bhiwani, Mahendergarh, Palwal), the approval process typically includes:

If you fall under UHBVN (Sonipat, Panipat, Karnal, Kurukshetra, Ambala, Yamunanagar, Kaithal, Rohtak, Jhajjar), the process is similar — but approval timelines and inspection stages vary.

As fixed charges and energy tariffs rise every year, your avoided grid cost rises with them — improving solar returns automatically.

Every ROI model we prepare accounts for:

This is why accurate modelling matters as much as panel selection.

Average district-level generation (kWh/kWp/day):

For financial modelling, we always use conservative generation values to ensure realistic payback calculations.

Exporting power should not be your primary strategy. With rising tariffs, maximum internal usage delivers the highest savings.

Plan your project at 4.5–5.0 kWh/kWp/day unless validated by an actual shading assessment.

Substandard modules and unreliable inverters may look profitable in calculations but reduce generation and ROI in the long run.

Most delays in Haryana occur due to weak roofing sheets, unclear load capacity or ageing RCC roofs that cannot support mounting loads.

This is the most common modelling gap EPCs ignore. As charges rise annually, solar economics become stronger — if calculated correctly.

Most EPC companies talk about solar as if it’s the same everywhere.

It isn’t — especially in Haryana’s industrial belt, where load patterns, dust levels, regulatory rules, and roof structures aren’t “standard.”

As a solar installation company for large-scale businesses, we know this because we’ve worked across factories, manufacturing plants, mills, cold storage units, institutions, and commercial facilities — and the results speak louder than proposals.

We don’t copy-paste designs.

Every project starts with shade analysis, structural feasibility, load mapping and real ROI modelling based on current DHBVN/UHBVN regulations.

No inflated ROI numbers. No fantasy generation claims. Just conservative and realistic numbers that you’ll actually hit.

Some businesses run 24/7, some only operate 8–10 hours, some have limited roof load capacity, some need hybrid or ready future-battery alignment. So, we design the system for your reality — not to drag you toward a fixed package.

Whether it’s CAPEX or OPEX, we plan around:

You don’t need to deal with multiple authorities, documents, submission errors, or delays.

We handle end-to-end coordination — net metering, DISCOM documentation, safety compliance, inspection and commissioning.

You stay updated — without doing the legwork.

The price we give is the price that stays.

We hand over:

So you know exactly what you’re getting and what we’ll support.