For most Indian businesses, electricity is no longer a predictable monthly expense. It has become

Read MoreChoosing the Best Solar System for Industries is not just about going green — it’s about maximizing ROI, ensuring energy reliability, and meeting future energy demands. The push for energy efficiency, cutting down costs, and running a greener business isn’t just a trend anymore, it’s becoming the new standard across industries. And when you look at where things are headed, solar power for industrial use is one of the smartest and most future-ready choices out there.

But here’s where things get tricky…

If you’re planning to install solar in an industrial park, the type of solar system you choose for your warehouse, manufacturing units, factories and industry isn’t just a technical decision, it can impact your budget, your energy output, how easily you can scale in the future, and even how smoothly you get through all regulations barrier.

And so, one question comes up again and again, especially if you’re managing or developing industrial spaces:

“Should we go with a ground-mounted solar system or a rooftop solar system?”

You’re not alone who is not able to decide. We’ve seen facility managers, sustainability officers, and business owners sit through weeks of meeting and not able to come to a viable and economical decision.

Sun Photonics is providing you a detailed guide. It will not only help you to decide but also make you understand, how will it work.

A ground-mounted solar system is installing solar panels on land, not at rooftops. You’ll often see these in large industrial setups, commercial campuses, or utility-scale farms where there’s no shortage of open space.

Unlike rooftop solar systems that are stuck with the limitations of your building, like roof size, angle, or shade. Ground-mounted solar gives you more control. You can design it exactly the way you want, adjust the tilt, and place it for maximum sun exposure.

Honestly, if you’ve got unused land in your industrial park or logistics zone just sitting there, this might be your golden opportunity to turn it into an energy asset.

At first glance, it might just look like a bunch of panels on a field, but there’s a well-oiled system working behind the industrial ground-mounted solar plant. Here’s a quick breakdown of what makes it tick:

Before knowing about Rooftop solar system you have fully check the advantages of ground mounted solar system for business.

RIPV (Rooftop Integrated Photovoltaics) solar system is just solar panels installed on the roof of a building, usually a factory, warehouse, or commercial unit. You might also hear it called BIPV (Building-Integrated Photovoltaics) when it’s built into the structure during construction, but in most industrial cases, it’s added later into existing rooftops.

If you’re running a setup in a tight urban industrial zone, where land is expensive, or there’s simply no extra space, RIPV might be your best bet. You’re basically turning unused rooftop real estate into a clean energy source. No need for land purchase, no extra footprint, and yes, you’ll start seeing the drop in your electricity bills.

It’s especially popular for self-consumption, meaning the power generated is used right there on-site. But if you’re producing more than you need? No problem, you can feed the extra back into the grid.

Here’s what goes into it, without all the jargon:

Also, check the benefits and disadvantages of rooftop solar for industrial sites.

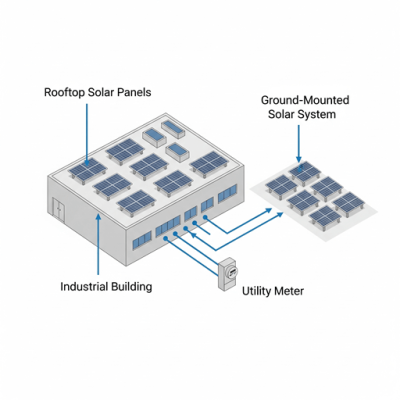

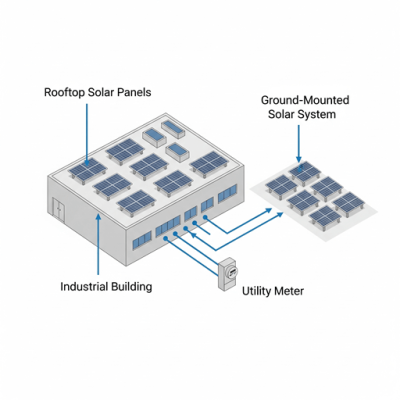

Let’s look at how to identify the best solar system for industries based on real-world application, layout constraints, and performance outputs. At the end of the day, whether it’s a ground-mounted setup or rooftop solar, both systems work similar, they turn sunlight into usable electricity. But how they do it, and how well they fit into your existing setup, is where things start to differ.

In industrial environments, it’s not just about generating power, it’s about how the system fits into your layout, integrates with your infrastructure, and supports your long-term goals. Ground-mounted and rooftop systems might work on same principal, but they take very different paths to get there.

Let’s break down what that means in practice, especially if you’re trying to decide which one’s the better fit for your site!!!

Let’s explore how each system functions practically within the industrial setting, including the components involved, system design strategies, and power flow!!!

This comparison helps facilities make a better-informed decision when choosing the best solar system for industries in terms of setup and power distribution.

| Aspect | Ground-Mounted Solar System | RIPV (Rooftop Integrated PV) |

|---|---|---|

| Installation Location | Open land adjacent to or near the industrial facility | Existing rooftops of factories, warehouses, or sheds |

| System Design | Rows of solar panels on steel/galvanized structures with optimized tilt | Panels on RCC, PEB, or sheet metal roofs, following roof tilt or custom angle |

| Space Requirement | ~4–5 acres per MW (Fixed tilt) | ~10,000 sq. ft. per 100 kW |

| Power Flow | DC from panels → inverter → HT/LT panel or export to grid via Open Access | DC from panels → inverter → LT panel for internal load or export via net metering |

| Usage Model | Open Access, Captive Power Plant, Group Captive | Net Metering, Self-consumption, Hybrid with storage |

| Energy Export | Typically through grid under Open Access (wheeling) | Export excess to DISCOM under net metering (state policies apply) |

| Scalability | Highly scalable; additional land can increase capacity | Limited to available rooftop space and structural load |

| Structural Limitations | Minimal; does not depend on building load | Depends on rooftop strength and layout |

| Installation Time | 90–120 days (subject to land readiness) | 45–90 days (faster turnaround) |

| Operations & Maintenance | Easy ground-level access; suitable for automated cleaning systems | Access via rooftop ladders or hatches; manual cleaning and inspection needed |

| Battery/Hybrid Compatibility | Easily integrated with storage or hybrid inverter systems | Possible but adds load to rooftop; used more in hybrid or critical load zones |

| Ideal For | Industrial parks with idle or underutilized land | Units with high electricity demand and limited land availability |

| Common Industrial Use Cases | SEZs, textile parks, chemical clusters, logistics hubs | Auto manufacturers, FMCG factories, electronics assembly units, cold storage plants |

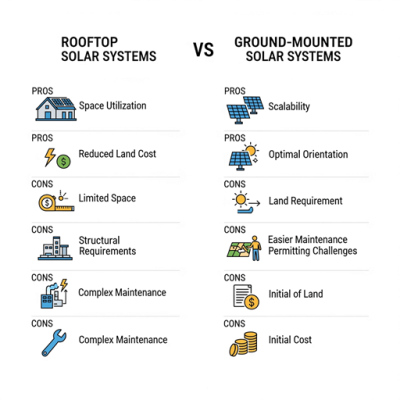

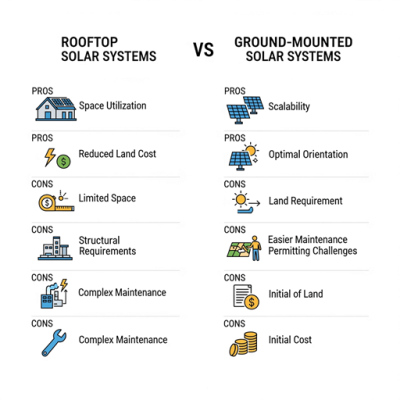

Space Utilization & Structural Requirements

When you’re planning a solar setup for your industrial facility, one of the first things to think about is how much space you actually have, and whether your structure can support it.

A ground-mounted system might be ideal if you’ve got open land just sitting there. You get full control over layout, orientation, and capacity, without depending on your building’s structure.

On the flip side, if land is limited or too costly, rooftop solar (RIPV) makes a lot of sense. It puts your existing roof to work, but only if it’s strong enough to handle the weight and layout of solar panels. That’s why checking the structural integrity of your roof is a must before jumping in.

In short, your choice depends heavily on how your space is set up, and how much of it you’re willing (or able) to use.

| Parameter | Ground-Mounted System | Rooftop Integrated PV (RIPV) |

|---|---|---|

| Land/Roof Requirement | 4–5 acres per MW | ~10,000 sq. ft. per 100 kW |

| Dependency | Requires dedicated land | Utilizes existing rooftop |

| Structural Load | Ground-based, no dependency on building | Requires roof to support ~15–20 kg/m² |

| Shading Concerns | Easily avoidable with proper layout | Needs shading analysis; nearby objects may block sunlight |

| Design Flexibility | High — orientation and tilt can be optimized | Moderate — depends on roof angle and structure |

| Ideal For | Facilities with land availability and large power needs | Space-constrained units aiming for self-consumption |

When it comes to choosing between Ground-Mounted solar system or (RIPV) rooftop solar systems, it’s not just about how much energy you’ll generate, it’s also about what it’s going to cost you to build, run, and maintain the system over next 25 years. Weighing upfront and lifecycle costs is essential in figuring out the best solar system for industries with long-term energy savings.

Let’s break it down.

These systems usually come with a higher upfront cost, and here’s why:

You’re not just installing panels, you’re prepping land, doing civil work like piling and fencing, laying longer cable routes, and often adding external inverter stations. It all adds up.

On average, expect to spend around ₹45–55 lakh per 100 kW (and that’s without factoring in the land cost).

But there’s a flip side:

Maintenance is a lot simpler since everything is on the ground, making cleaning and repairs safer and faster. With professional solar plant maintenance services in Gurugram, this also brings long-term O&M costs down per unit.

If you’re going rooftop, your starting costs are usually ₹38–45 lakh per 100 kW, a bit lower than ground-mounted systems. That’s because you’re not dealing with land development or heavy civil work.

But that doesn’t mean it’s plug-and-play. Costs can shift depending on:

Operational costs here are pretty low, but here’s the catch:

Cleaning or repair work can get tricky. Large industrial sheds may require scaffolding, safety gear, or even cranes to safely reach the panels, especially if your facility is spread across multiple levels.

In short:

Ground-mounted = higher setup cost, easier to maintain

RIPV = lower install cost, a bit more effort in upkeep

These factors make ground-mounted options strong contenders when evaluating the best solar system for industries with high energy needs. You can angle the panels perfectly, space them out just right, and position them to soak up the most sunlight year-round.

Since they’re usually free from shade and sit in open space, energy generation per kW tends to be higher.

Plus, you can easily integrate tracking systems that follow the sun during the day, which can boost efficiency by 10–25%, depending on the tech.

If you’re thinking big, say, a 1 MW+ plant, you can expect a solid 4.5 to 5.2 units per watt/year under Indian conditions, as long as you use quality components and install in a high-irradiance zone.

Rooftop Integrated PV (RIPV)

Rooftop systems don’t offer the same freedom. You’re working with the roof space you’ve got, and that means dealing with:

Still, well-designed RIPV systems can perform surprisingly well. In states like Gujarat, Haryana, or Rajasthan, where sunlight is strong, you can get 3.8 to 4.8 units per watt/year, which is nothing to scoff at.

Panel efficiency itself isn’t the issue, rooftop and ground systems use similar panels (typically 17–21% efficiency). What affects RIPV more is the site-specific limitations and how well the system is engineered around them.

Comparing long-term upkeep and downtime helps reveal the best solar system for industries from an operational cost perspective. It’s not just the installation bill you need to worry about. Long-term operation and maintenance system affect your total return on investment (ROI) of your solar power plant.

Ground-mounted systems are easier to access, so cleaning, inspections, and replacements are simpler and often cheaper over time.

RIPV systems, on the other hand, may require extra safety gear or lifting equipment for basic upkeep, especially on large or high rooftops. That can add a bit to the ongoing costs, but it’s usually manageable with the right planning.

| Parameter | Ground-Mounted System | RIPV (Rooftop Solar) |

|---|---|---|

| Accessibility for Maintenance | Easy (open layout) | Moderate to Difficult (roof access) |

| Cleaning Requirements | Standard | Frequent (more dust/debris) |

| Cooling Efficiency | Higher (better airflow) | Lower (heat island effect) |

| Risk of Physical Damage | Low | Moderate (roof work, foot traffic) |

| Average Maintenance Cost | ₹1.5–2/Watt/year | ₹2–2.5/Watt/year |

| Expected Lifecycle | 25–30 years | 25–30 years |

| Downtime Risk | Lower | Slightly higher (due to access or shading issues) |

For large-scale industries with space availability, ground-mounted systems are more maintenance-friendly and cost-efficient over the system’s lifetime

When it comes to actually putting solar to work in industrial environments, think large factories, logistics hubs, and manufacturing parks, both Ground-Mounted solar system and Rooftop (RIPV) solar systems have proven their worth. But as always, the best results depend on where and how you use them.

Here’s a quick look at how these systems hold up in the real world, with all their strengths and trade-offs.

A heavy-machinery manufacturer in Rajasthan turned a patch of unused barren land inside their industrial estate into a 2 MW ground-mounted solar plant, and it paid off fast.

What they achieved:

The challenge?

Dust and sand, a common headache /issue in that region which effect the maintenance.

The Solution:

They implemented a bi-weekly waterless cleaning system using specialized brushes, backed by AI-powered performance monitoring. It kept the panels clean and the output steady without wasting water.

In Bawal, a cold-storage logistics company decided to install a 600 kW rooftop solar system across their warehouse rooftops, mainly to power energy-hungry refrigeration units.

What they achieved:

The challenge?

Their warehouse roofs had structural load limits and weren’t easy to access for cleaning.

The fix:

They went with lightweight solar panels and added walkways during installation so the maintenance team could do their job safely and efficiently.

Going solar isn’t just a smart financial move, it’s also a big step toward meeting environmental goals and ticking the right boxes for regulatory compliance.

Whether you’re setting up a Ground-Mounted system or a Rooftop (RIPV) installation, you’ll want to think beyond just the numbers. Things like government policies, land use, and ESG commitments play a major role in your project’s long-term success.

| Environmental Factor | Ground-Mounted | RIPV Rooftop |

|---|---|---|

| Land Use | Requires 4–5 acres per MW; may disturb local ecology | Zero land use; utilizes existing built-up infrastructure |

| Heat Island Mitigation | Neutral impact | Reduces building heat load, especially in warehouses/factories |

| Rainwater Harvesting Disruption | May require reengineering of drainage | Rooftop systems can be designed with integrated drainage systems |

| Carbon Footprint Reduction (per MW) | ~1,200–1,400 tonnes/year | ~1,000–1,200 tonnes/year |

Going solar isn’t just a smart financial move, it’s also a big step toward meeting environmental goals and ticking the right boxes for regulatory compliance.

Whether you’re setting up a Ground-Mounted system or a Rooftop (RIPV) installation, you’ll want to think beyond just the numbers. Things like government policies, land use, and ESG commitments play a major role in your project’s long-term success.

Between Ground-Mounted solar and Rooftop solar, the clear winner for scalability is ground-mounted.

Why?

Because with open land, you can simply add more panels as your energy needs grow. The layout is flexible, infrastructure is easier to upgrade, and you’re not limited by rooftop space or structural load.

Rooftop solar systems (RIPV), while efficient and space-saving, hit a ceiling — literally. Once your roof’s full, you’re out of room unless you start removing old panels or rebuilding the structure.

Whether you go rooftop or ground-mounted, grid integration is a big part of the equation — especially if you’re looking to offset daytime loads or earn credits from surplus generation.

Net metering for industrial solar is supported in both systems, but ground-mounted setups are often better suited for open access models, where you generate energy off-site and wheel it to your facility. This is ideal for large-scale users spread across multiple locations.

RIPV systems, on the other hand, are more geared toward on-site self-consumption and net metering within the same premises. Simple, effective, and perfect for reducing bills fast.

Why choose one when you can combine both?

Many industrial parks are now adopting hybrid solar models — using RIPV for rooftops and ground-mounted systems for excess land. This gives you the best of both worlds:

Hybrid setups also allow smarter load management and can be designed to prioritize rooftop power for critical loads, while ground-mounted systems feed into the main grid or storage.

There’s no one-size-fits-all answer when it comes to solar energy adoption in industrial settings. Whether you go with a Ground-Mounted Solar System or a Rooftop Integrated Photovoltaic (RIPV) setup, the “right” choice comes down to your space, scale, budget, and long-term vision.

Both systems are proven, bankable, and environmentally forward — the key lies in aligning them with your business’s operational flow and energy strategy.

Still unsure? Many industrial giants are now combining both — installing rooftop systems first, then expanding with ground-mounted capacity as demand grows. This hybrid approach offers flexibility, financial balance, and a solid ESG narrative.

If you’re ready to invest in the Best Solar System for Industries, get in touch with our expert team today for a customized solar proposal.

Solar isn’t just about cutting electricity bills anymore — it’s about building smarter infrastructure, lowering carbon risk, and staying future-ready in a changing energy landscape.

Start where you stand — just don’t stand still.

Still have questions or need expert advice tailored to your facility?

Get in touch with the large scale solar EPC company in Haryana and solar specialists at Sun Photonics — we will help you to understand which is the best solar system for your industry. we’re here to guide you every step of the way.

Jatin Singh is a content developer at Sun Photonics Pvt. Ltd., specializing in creating impactful content for solar energy solutions. With a background in tech and health, he has previously worked in digital marketing and pharma. Passionate about sustainability, and currently exploring all things about solar!

Approval by an Expert:

“This content is reviewed and approved by Dr. Sujata Bhaker, who holds a Doctorate in Renewable Energy and brings over 10 years of industry expertise.”

Both systems have pros and cons—ground-mounted is more scalable and easier to maintain, while rooftop (RIPV) delivers quicker ROI on limited space. The “best” choice depends on your available land, structural capacity, and long-term expansion plans.

Typically you need about 4–5 acres per 1 MW of installed capacity for a fixed-tilt ground-mounted system—ideal if you have underutilized land in your industrial park.

• Ground-mounted: ₹45–55 lakh per 100 kW (excluding land cost)

• Rooftop (RIPV): ₹38–45 lakh per 100 kW

Costs vary with site prep, brand choice, and civil work.

ROI for ground-mounted systems often occurs in 4–5 years due to higher yield and lower O&M, while rooftop systems generally see payback in about 5–6 years, depending on net-metering rates.

Yes—hybrid setups let you maximize rooftop space for critical loads and scale further on unused land, optimizing generation and load management across your facility.

Ground-mounted systems have easy ground-level access and cost ₹1.5–2 INR/Watt/year, whereas rooftop systems may require ladders or scaffolding and run ₹2–2.5 INR/Watt/year, with cleaning every 1–2 months in dusty areas.

For most Indian businesses, electricity is no longer a predictable monthly expense. It has become

Read MoreWinters expose every weakness in a rooftop solar system — moisture, fog, temperature swings, metal

Read MoreAs India accelerates its path toward clean and sustainable green energy, the role of Solar

Read MoreIndia’s energy sector is transforming rapidly, and commercial rooftop solar has emerged as a core

Read MoreIntroduction: Why BIPV Is Gaining Traction in India (2026 Update)Cities are growing taller, streets are

Read More